|

|

|

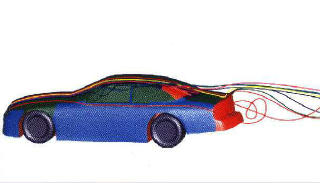

DAYTONA BEACH, Fla. (Feb. 2, 2000) -- Ask NASCAR drivers what they all need more of and the answer is simple -- time. More time behind the wheel, more time for sponsor and media appearances and more time to spend with their families. So as NASCAR grows and demands on its participants increase, where will teams look to find the time? NASCAR 2000 looks at the world of virtual reality and the role computers will play in the future of NASCAR. Much more than video games, computer simulated testing of everything from tracks to tires is in its infancy in NASCAR, but the potential to create more time for teams and drivers appears limitless. With virtual reality, computer software tools create 3-D, fully functional, realistic models, enabling people to become involved in a simulated environment to develop and practice skills, rehearse procedures and troubleshoot problems. As technology evolves, race teams will be able to spend a few hours racing at their track of choice under any conditions without ever leaving the shop. Changing spoiler angles, shock setups or tire pressure will be possible at the touch of a button. "The whole nature of engineering is changing in the way we build physical pieces," said John Valentine, chief engineer for Ford Racing Advanced Technology. "In the past, we would build a prototype -- each piece by hand -- and then test it to see what worked and what didn't. Then we would rebuild it two or three more times. In order to speed time to market, a lot of this is now being done on computers."Ford's Taurus was designed and on the race track in a mind-boggling nine months, thanks in large part to physical scale models and virtual wind tunnel testing.

"We used to go to the wind tunnel with two or three front fender shapes, different grill openings and a few body side configurations," Valentine said. "With the computer, we can change anything we want without having to spend the time and the money to take all the equipment and technicians to the wind tunnel. Time is money for the teams and guys are going to have to find ways to do things quicker and faster."Although virtual reality is not a new technology, motorsports applications are just being developed. "Airplane pilots have been using training simulators for years," said Carol Gunther-Mohr of Research Triangle Institute in Raleigh, N.C. "Between advancements in software tools and computer hardware, I think the potential for growth in this area is limitless."Racing provides the perfect environment for the use of virtual testing. With some form of racing or testing going on nearly every week, and tracks having relatively controlled characteristics, computer models can be designed and verified quickly. "The growth of NASCAR engineering stables is the wave of the future," Valentine said. "It's more efficient to do things in a virtual way. The days of racing's romantic era when a couple of guys could throw a rope over a tree branch, drop an engine in a car and go win Daytona are over." "It will be interesting to see what role NASCAR will play in the growth of virtual testing," Gunther-Mohr added. "They could develop virtual tracks where tire companies could come in and test tires and teams could test their cars."For now, manufacturers are leading the way. "Our goal is to have the car roll off the truck ready to go," Valentine said. "Right now, a lot of time is spent on simple trial and error during practice and qualifying. If we can eliminate the trial and error, it will give the teams more time during the week to concentrate on different ways to find the competitive edge."With virtual wind tunnel testing already being used to improve the aerodynamics of NASCAR vehicles, Valentine believes the next area of growth will come in the areas of engine modeling and vehicle dynamics. Haas Automation Inc., of Oxnard, Calif., has done work with Hendrick Motorsports using Computer Numeric Control (CNC) machines, capable of replicating engine parts within tenths of a micron -- the width of a human hair is approximately 70 microns. Engineers can input Computer Aided Design (CAD) drawings directly into the CNC machines, bringing the drawings to life and creating identical, intricate parts of every shape and size available. Before computer automation, it took nearly 18 hours to manufacture a cylinder head for a race car. With a CNC machine, time is cut to about three hours, the parts are identical and the machine can run 24 hours a day. "Gone are the days of old Fred turning the lathe in a dark, dingy machine shop that smelled like cutting oil and had metal shavings all over the floor," Valentine said.So, are computers the answer? "Millions of adjustments can be made to a race car," Valentine said. "Computers just help you narrow the field of reference. If you have 15 carburetor setups and the computer can weed out the top three, it will save you a lot of testing time. © 2000 NASCAR Guest Book - E-Mail ® AMA Pro Racing NASCAR Winston Cup Series NASCAR 2000 NASCAR Busch Series NASCAR Goody's Dash Series NASCAR Slim Jim All Pro Series NASCAR Craftsman Truck Series NASCAR Touring ASA-ACDELCO Racin' Florida Style |